TECHNOLOGY DESCRIPTION

Technology based on the secondary use of materials already built into the construction of the road surface. It is used where the load capacity of the road is exhausted and the road surface is so damaged that the reconstruction of a number of layers is essentially required. A sign of such damage is the appearance of multiple cracks, frequently accompanied by numerous potholes and surface deformations, particularly in the vehicle tracks or at the road edges.

Cold state recycling technology on site enables the improvement of the quality of the base and/or subgrade construction of the layer in a thickness of 12 – 25 cm through the addition of hydraulic and asphalt binding agents or by filling with gravel according to the proposed formulation.

Binding agents used:

- Hydraulic binding agent – cement and other hydraulic road binding agents;

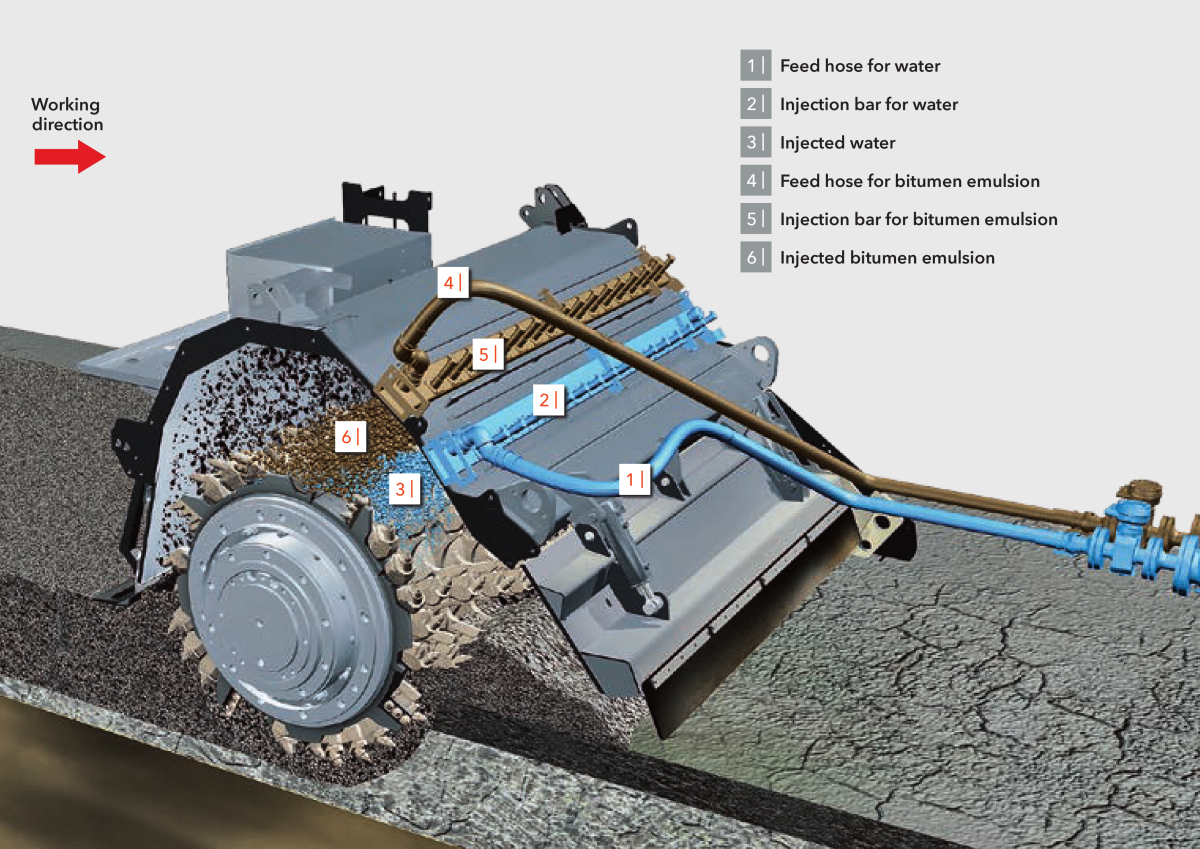

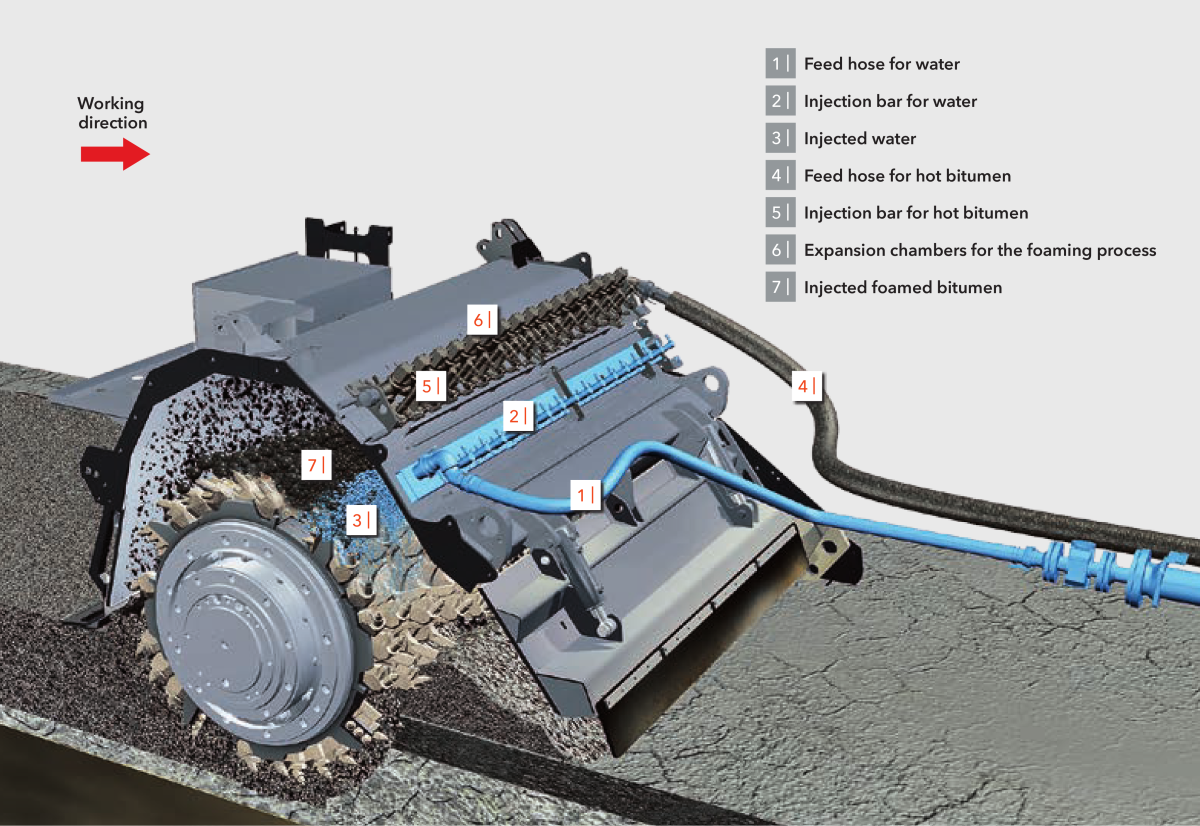

- Asphalt binding agent – asphalt emulsion or asphalt foam (asphalt foam is generated directly in the recycler by mixing asphalt and water in a foaming machine);

- Combined binding agent (mixture of cement and asphalt emulsion or cement and asphalt foam).

Filling with gravel

If the gradation curve of the original layer is unsuitable, filling with a suitable grading of gravel directly onto the surface of the layer is performed before the recycler.

Milling and granulation of existing layer

This is performed by traverse with the recycler on the original layer by the activity of the milling (mixing) drum to the prescribed depth.

We distinguish between two phases:

Pre-milling and re-profiling (used upon adjustment of transverse and lengthwise shape of road surface, height adjustment of profile grade or for homogenisation of layers) The grain fineness is homogenised to the prescribed thickness by pre-milling of the existing layer(s). At the same time gravel spread before is mixed into the pre-milled compound, thus adjusting the gradation curve according to the proposed formula. This is used to advantage in adjustment of a number of layers with varying grain fineness, when the entire complex of layers is homogenised by pre-milling and re-profiling, and shaped to the prescribed transverse and lengthwise incline. This phase may be omitted in the technology on the precondition that it is not necessary to adjust the layer in terms of height and that homogenisation is not required.

Actual recycling

In this phase the original compound is degraded and mixed with further components (binding agents, water, gravel).

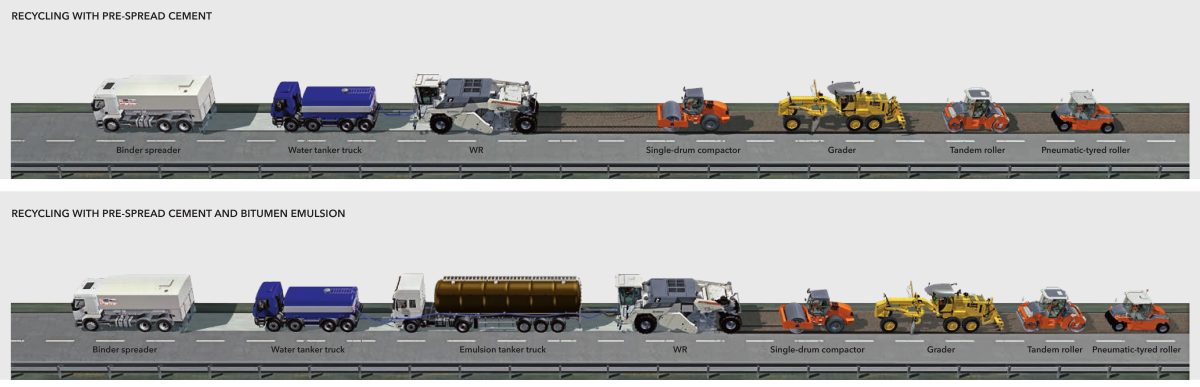

Dosing of binding agent, mixing of compound

Each binding agent is dosed separately in the type and quantity stipulated by the laboratory. Cement or other hydraulic binding agent is spread directly onto the recycled surface of the roadway by a dosing device.

The process of dosing the asphalt binding agent (asphalt emulsion, asphalt foam) and water is automatically regulated by an electronic pump, depending on the traversing speed and the width of adjustment in such a manner as to ensure that the prescribed quantity is always dosed.

Spreading and compacting of compound

The homogenised compound is spread using a grader to the required height and lateral incline. Compacting is performed according to the rolling scheme by a steamroller equipped with vibration, either by a towing vehicle or tandem roller.

Hrvatski

Hrvatski

FREKOMOS CZ

FREKOMOS CZ

FREKOMOS SK

FREKOMOS SK