Hot recycling on site

Hot state recycling on site is an economic and ecological method of repairing asphalt covers of road surfaces. This progressive technology is used for re-shaping and the improvement of quality for the existing asphalt cover and it is also possible to lay a new top surface in the same working cycle (REPAVE and REMIX PLUS).

Advantages of hot recycling on site

- Low economic and time demand factor of repair

- Extension of the life span of asphalt cover or roadway construction

- Environmental effect (saving of natural resources, energy savings, reduction of volume of waste)

- Remix and remix plus are jointless technologies, because the transverse and lengthwise joints are treated by heat directly during laying, thus attaining the same degree of compaction as in the middle of the working lane.

-Increased driving comfort and safety for drivers.

Technology and areas of use

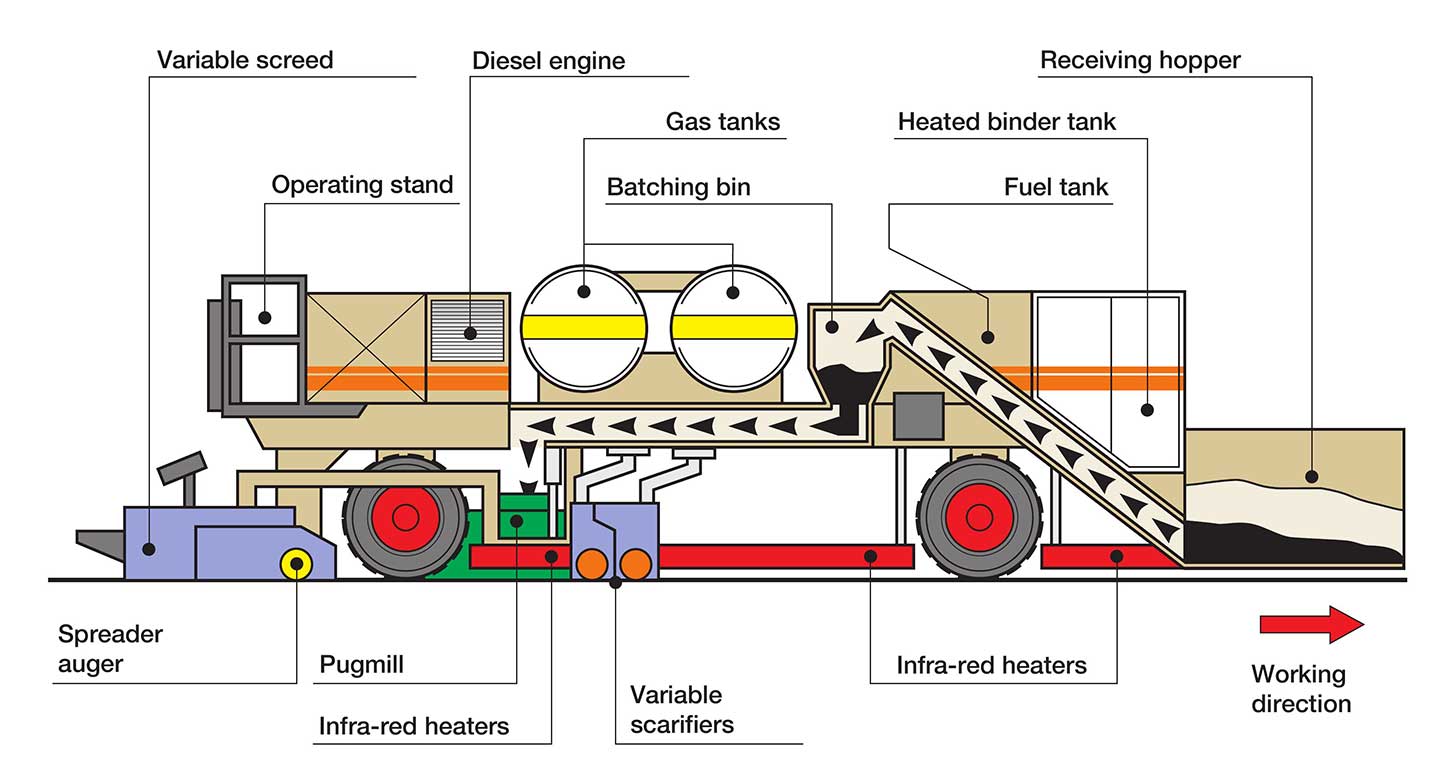

The machinery for hot state recycling on site comprises pre-heaters, which gradually heat the repaired asphalt layer to the required temperature using propane-butane infra-red heaters, a remixer, which loosens the heated layer with a milling drum and thoroughly mixes the thus obtained compound with other applicable added components (asphalt, gravel, asphalt compound). The final part of the remixer comprises of independent heated strips, which spread, profile and pre-compact the homogenised compound. Then there follows the final compacting of the recycled compound by steamrollers. The described technology essentially enables the performance of four basic alternatives of hot state recycling asphalt layers.

The most widely used technological alternatives to hot state recycling on site are REMIX and REMIX PLUS, less used technological alternatives are RESHAPE and REPAVE.

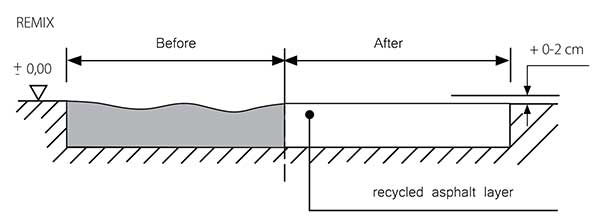

REMIX

Re-shaping of the roadway cover by recycling together with quality improvement of the compound of the asphalt layer

The original asphalt layer is adjusted to the required physical-mechanical properties through the addition of the necessary components. The construction of the remixer enables the addition of the asphalt binding agent and asphalt compound according to the prescribed formula. 5 to 30% of new materials are usually added for the purpose of stabilising and softening the original asphalt compound.

REMIX technology comprises the following steps:

- Spreading of added gravel onto surface of roadway (only in the case of addition of actual gravel),

- Heating of asphalt compound of layer designated for recycling,

- Loosening of heated asphalt compound,

- Addition of required materials (softening admixtures, road asphalt, pre-packaged gravel compound),

- Mixing of heated asphalt compound with added materials,

- Re-laying of treated asphalt compound,

- Compacting of treated asphalt compound

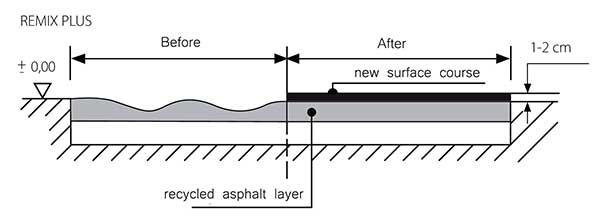

REMIX PLUS

Re-shaping of the roadway cover by recycling with quality improvement of the compound of the asphalt layer, together with laying of new top surface

As with the REPAVE alternative this concerns the creation of two asphalt layers simultaneously. The original asphalt cover is treated with REMIX technology with the help of the addition of the required components onto the basic recycled layer, and a new plus top surface is laid on this in a single working cycle.

REMIX PLUS technology comprises the following steps:

- Spreading of added gravel for adjustment of grain fineness of recycled compound,

- Heating of asphalt compound of layer designated for recycling,

- Loosening of heated asphalt compound,

- Addition of softening admixtures or road asphalt to existing loosened layer,

- Mixing of heated asphalt compound with added materials,

- Re-laying of treated asphalt compound by first heated strip,

- Laying of new asphalt compound of top surface (injected layer) by hot on hot system by second heated strip, thickness of layer 10 – 40 mm,

- Compacting of asphalt complex of layers (re-laid recycled layer + new top surface layer)

RESHAPE

Re-shaping of the roadway cover by recycling in the case that the existing binding agent demonstrates the required physical-mechanical properties.

- Heating of asphalt compound of layer designated for recycling,

- Loosening and disaggregation of compound of layer designated for recycling,

- Levelling of loosened and disaggregated asphalt compound in transverse and lengthwise direction,

- Compaction of levelled asphalt compound

In case of necessity of improving anti-skid properties it is possible to use breaking by pre-packaged gravel 8-11 or 8-16

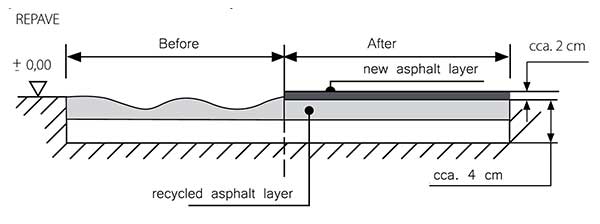

REPAVE

Re-shaping of the roadway cover by recycling together with addition of thin layer of quality asphalt compound

- Heating of asphalt compound of layer designated for recycling,

- Loosening and disaggregation of compound of layer designated for recycling,

- Laying of new, levelled asphalt layer (performed concurrently in a single working cycle)

- Compaction of both layers simultaneously.

Reinforcement of the surface by 10 to 40 mm can be attained by the addition of new compound.

Strojevi koji se koriste

Wirtgen RX 4500

Remixer Wirtgen RX 4500 is hot recycling machine with a continuously adjustable working width between 3.00 m and 4.50 m for the large-scale rehabilitation of bituminous bound road surfaces in a single operation. Powerful, individually connectable infrared heaters heat the asphalt concrete gently and evenly.

Working width: 3000 – 4500 mm

Working depth: 0 – 60 mm

Engine power: 1.445 kW

Operating weight: 47.900 kg

Wirtgen HM 4500

Wirtgen HM 4500 is panel heating machine, with a maximum heating width of 4.50 m, the self-propelled heating machine is ideal for use in combination with the Remixer 4500. The heating power of the infrared heaters can be precisely adjusted using the centrally positioned gas regulation station.

Heating width: max 4.500 mm

Heaters: infrared

Heating power: 2.260 kW

Tank: 6000 L

Engine power: 102 ks

Operating weight: 19.700 kg